Type 5 construction really should be at least 2 if not 3 separate categories. Also known as lightweight construction, there are 4 distinct styles, which mark refinements in process and materials.

type 5 construction is the Most flammable, but also the most common form of residential construction.

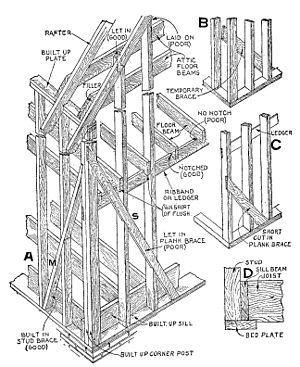

Balloon framing

Balloon framing followed heavy timer Construction as a method of framing a building. Balloon Framing replaced heavy timber construction in the 1830’s and continued to be used until the post war period.

Balloon framing is characterized by Long continuous studs which run from the foundation to the roof of the building. typically used for 2 or 3 floor structures, the floors joists sit on a Ledger board. The studs are notched, and a ribbon board attached.

This is the Key characteristic which leads to balloon framing being a problem for the fire service. these buildings were often constructed without blocking between studs, resulting in void spaces running from the foundation to the attic, and due to the way the floor beams attach to the studs, that void in all likelihood continues under the floor.

Platform Framing

Platform framing has taken over construction as it is easier to erect. a foundation is Constructed, and a platform making up the first floor is constructed. Walls are then built on top of the platform and, another platform constructed for the second floor. The wall cavities are not continuous, and do not join the Ceiling voids.

Platform Framing, which has 3 basic types

Full dimensional

up to 1965 – lumber used was true to the dimension, roofs were framed not trussed. floors tongue and groove planking, as are walls/roof.

This Bungalow is half demolished, but you can see the structure quite clearly. 2×4 studs, 2×6 floor joists. tongue and grove planking for the subfloor and exterior sheathing and no roof trusses.

Lightweight – 1965-2000

still predominately constructed with dimensional lumber, plywood (and later OSB) replaces tongue and grove planks for flooring and sheathing. these feature non true side dimensional lumber as a result of changes to the sizing standards in 1964. additionally large spans are addressed with steel I beams.

Mostly a rarity today, this house is being constructed without the use of I Joists or Floor trusses, and is very typical of lightweight construction found in buildings from the 80’s and 90’s. Earlier versions likely would have used plywood rather then OSB for the sheathing however.

the roof will be constructed of pre-manufactured roof trusses, the pieces of which are joined with metal truss connector plates.

note the use of 2×10 dimensional lumber for floor joists. The large free span of the space is carried by a steel I beam, and the joists are supported by joist hangers to attached to inset dimensional lumber in the beam.

Note the walls are 2×6 dimensional lumber, which is common in modern construction as it allows for r40 insulation Bats to be placed into the wall.

Hopefully something that will be fixed, this stud directly under the beam should be beefed up to properly carry the loads.

UltraLightweight

from 2000 on the prominence of manufactured wood trusses and beams, as will as composite walls have fundamentally changed the makeup of lightweight wood frame construction. These buildings i describe as ultra lightweight, as their structures are even lighter then lightweight construction.

this house makes use of wooden I Joists rather then dimensional lumber to support the Floors. I joists support longer spans then traditional dimensional lumber and are more rigid.

Note sections of the wall are entirely foam. the OSB sheathing is only used where required to give the wall a shear rating. Variations of this have actually done away with wood sheathing all together and used metal strapping to achieve the required shear strength in the wall. The Shear rating is to allow the wall to resist sideways forces.

Another Variation makes use of wooden Parallel Chord Floor Trusses. these are made up of dimensional lumber, and appear to be joined using glue and joinery. Note that Steel Beams are rarely used – The trusses are attached with Joist Hangers to LVL Beams.

Below Laminated Venner Lumber (LVL) beams in use. they are easily identified by their OSB appearance and Orange coloring.

Additional Information

CMHC offers a guide to Canadian Wood Frame House Construction (PDF)